| Japanese green tea production keeps

tea green by steaming tea leaves and parching in order to stop fermentation. After

that, rough finishing is in the process of rubbing and drying. Finishing are in

the process of selecting rough finished tea and drying as well as blending. Hand

rubing production method. The purpose of rubbing tea is to force tea leaves in

order that tea leaves organization and cell membranes are destroyed so that its

ingredient will be obtained easily.In late 19th century (Meiji period), many hands

rubbing tea production methods are invented. After that good points of many production

methods were gathered and standardized to a tea production method ( 1953 method).

Hence standard hand rubbing tea production method was determined. |

|

| Steaming

Tea leaves are steamed in short time and cooled down rapidly (30seconds to

40 seconds.)

First rubbing

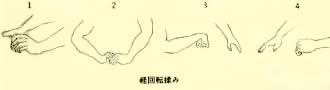

There are 3 process, Hafurui (selection tea leaves), Kaitenntumi (turning rubbing),

Tamatoki ( untied tea lumps)

In the process of Hafurui, steamed tea leaves are sifted out equally and make

tea leaves water 80%. (30 minutes to 50 minutes).

|

|

| In the process of Tamatoki.tea lumps

made from rubbing are untied.

In the process of Kaitentsumi, tea leaves are forced in order that water in

tea leaves evaporated

. In the beginning it is called Keikaiten (light turning).In the end of Kaitentsumi,

it is called Jukaiten (heavy turning).

Waters in tea leaves are reduced to 50% (40minutes to 50 minutes).

In the process of Tamatoki.tea lumps made from rubbing are untied. |

|

| First processing

After Tamatoki is done, tea leaves are out from tea hearth and cooled down

rapidly as well as equalized water in tea leaves in order to do finishing rubbing

easily.

|

|

In the process of Dengurimomi, tea

leaves are rubbed to shaped needle like shape. (10 minutes to 20 minutes.)

|

|

In the process of Kokuri, tea leaves

are shaped further and are polished to gloss. (10 minutes to 20 minutes).

|

|

| Drying

Tea leaves are sprinkled and turned over few times as well as dried. Water

of tea leaves reduced until 40% in this process. (30 minutes to 40 minutes).

There are many hand rubbing production methods such as Utita-ryu, Ogasamomikiri-ryu,

Kouzu-ryu,Kaisin-ryu, Kaitou-ryu, Kawakami-ryu, Kyoukai ryu, Seito-ryu, Seicho-tyu,

Kurakai-ryu, Tamuta-ryu.

|

|

| *Machine rubing

tea production method

Steaming machine

Steaming tea leaves is first process of tea production, therefore, steaming

determined tea quality.

This machine steamed in a short time in order not to make destroyed tea leaves

because tea leaves needs to undestroyed and keeps green by losing oxidization

ferment effect in after rubbing process. (30minutes) |

|

|

|

| Cooling machine

Steamed tea leaves are cooled as well as eliminate water of tea surface.

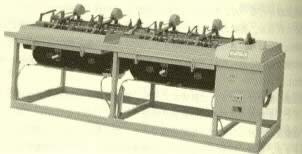

Rough rubing machine

Rough rubbing machine rubs tea leaves by heating steamed tea leaves and force

in order to make tea leaves soft as well as reduced water of tea leaves 50%. (45

minutes) |

|

|

|

| Second rubing machine

Second rubbing machine gatheres tea leaves and force gradually and turn in

order that tea leaves water equally spreaded and make tea leaves soft as well

as destroyed tea leaves organization. (20 minutes).

|

|

|

|

| Middle rubing machine

Tea leaves are dried by heat wind and shaped to twisted and keep water of tea

leaves surface as well as evaporate tea leaves water equally and be in order quality

and shape. (40 minutes)

|

|

|

|

| Redrying machine

Tea leaves are dried by heat wind and shaped.

Final rubing machine

Tea leaves after middle rubbing machine or redrying machine are heated indirectly

and rubbed in order to shaped to Sencha tea. Waters of tea leaves are reduced

to 75%. |

|

|

|

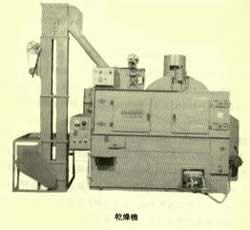

| Drying machine

Water of tea leaves after final rubbing is 11%-14%, therefore, Water of tea

leaves needs to be reduced 4%-5% in order to preservation. In this process, Tea

aroma and taste are created by heating.

|

|

|

|

|

|